Iimagnethi zeFormworkziyimfuneko kwaye zibalulekile izincedisi kuzo zonke iinkqubo zekhonkrithi zangaphambili. Ezi magnethi zenziwa kusetyenziswa ukusebenza okuphezuluNdFeB Magnetizinto eziphathekayo, ukwenza ukuba zibe yimveliso ephezulu yomgca. Ukuqinisekisa usetyenziso olululo, le magnethi yekhonkrithi yangaphambili ixhotyiswe ngezikhonkwane zoqhagamshelo lwasentwasahlobo. Ukongezelela, iqhosha layo kunye namacandelo ezindlu akhiwe kwiCarbon Steel okanye iStainless Steel 304, eqinisekisa ukuhlala kunye nokuphila ixesha elide.

Honsen Magneticsuye wagqibelelisa ubugcisa beemagnethi zestencil. Qhubeka ufunda ukuze ufumane ulwazi oluphangaleleyo kwizicelo zabo, ukugcinwa, kunye nefuthe labo lenguqu kushishino lwekhonkrithi ye-precast. NgeHonsen Magnetics, Iqela lethu leenjineli ezizinikezeleyo zangaphakathi ziyile ulungelelwaniso lwemagnethi lwangoku. Iimagnethi zekhonkrithi ezenziwe kwangaphambili zinamandla amangalisayo omhlaba wemagnethi kunye namandla anomtsalane, angaphezu kwama-200 ubunzima babo. Ukusebenzisana phakathi kwezixhobo ezinobuchwephesha ezinokungena zilungelelanisa utshintsho kulungelelwaniso lwemigca yentsimi ngaphakathi kwemagnethi nganye.

Xa sasiqalisa imveliso yeemagnethi zeformwork, sasijonge amathuba angenasiphelo. NgeHonsen Magnetics, Iqela lethu leengcali ezinetalente zemagnethi lizinikele ekwenzeni olu lungelelwaniso lwemagnethi luntsonkothileyo. Iimagnethi zekhonkrithi ezenziwe kwangaphambili ziqhayisa amandla amangalisayo omhlaba wemagnethi kunye namandla anomtsalane, ukodlula kangangama-200 ubunzima babo. Ukudityaniswa kwezinto ezinobuchwephesha ezinokungena kukhokelela kuhlengahlengiso lwemigca yentsimi ethe ngqo kwimagnethi nganye.

Ngexesha lesicelo, imagnethi yekhonkrithi yangaphambili incamathela ngokukhuselekileyo kwiqonga lokubumba intsimbi ngesiseko sayo. Oku kudityaniswa kwemagnethi kunye neqonga kwenza inkqubo yokuvalwa kwesekethe yemagnethi ebanzi, ebonisa amandla okubamba anamandla. Iimagnethi zestencil zigcina uzinzo, zithintela nayiphi na intshukumo, ukutyibilika, okanye ukushukuma, ngaloo ndlela ziphucula ukhuseleko kunye nobuhlobo bomsebenzisi.

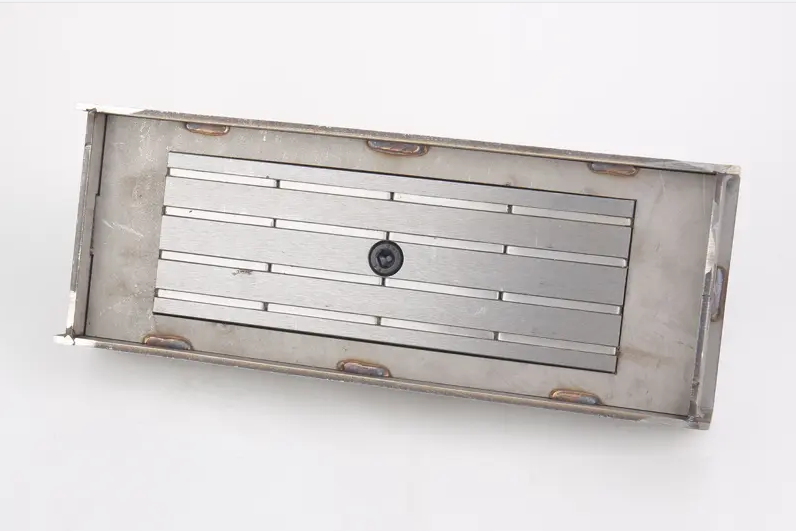

Imagnethi yetemplate yenziwe yiyunithi yemagnethi yetemplate ye-NdFeB eguqukayo, ibhloko yemagnethi egcinwe ngaphakathi kwecasing, kunye nezikrufu zokulungisa. Ngokudibanisa iimagnethi ze-neodymium kunye neepleyiti zentsimbi, senza isekethe yemagnethi eyomeleleyo eyenza amandla okutsala amandla. La mandla akhusela ngokufanelekileyo umthi okanye i-formwork yentsimbi kwindawo. Amaqhosha okulawula abekwe ngokufanelekileyo kumphezulu wemagnethi yekhonkrithi ye-precast. Xa iqhosha licofa, umazibuthe uvula isekethe yayo yamagnetic, ibambe ngokuqinileyo itemplate kwipleyiti yentsimbi. Ngokwahlukileyo, iqhosha lokuvala livumela ukubekwa kwakhona kwemagnethi ngokulula. Umazibuthe wetemplate unemingxuma emibini ephothiweyo jikelele phezulu, eyilelwe ukuthwala iiadaptha ezahlukeneyo. Iimveliso zethu zinokwenziwa ngokweemfuno zakho ezithile, zibonelela ngoluhlu olwahlukeneyo lwezicelo.

Kwincopho yeemagnethi zokuvala, kukho iswitshi yokuguqula. Kwimeko yokusebenza, ngokucofa eli qhosha, ibhokisi yemagnethi incamathela ngokukhuselekileyo isivalo eqongeni. Ukubandakanya i-lever ukuphakamisa iqhosha kubeka ibhokisi yemagnethi kwindawo evaliweyo, inikezela ukuba ishukumiseke.

- Amandla ancamathelayo ebhokisi yemagnethi axhomekeke kubukhulu beqonga kunye nokuguda. Imiphezulu etyebileyo negudileyo inika iziphumo eziphezulu. Ukongeza, amandla okucheba asecaleni axhomekeke kuzo zombini iintambo zebhokisi yemagnethi kunye ne-coefficient yokukhuhlana kwendawo yoqhagamshelwano.

-Kumacala omabini ebhokisi yemagnethi, kukho izikrufu ezibini, ezivumela ukudityaniswa kweeadaptha ezahlukeneyo. Olu phawu luququzelela ukuncamathelwa kweefomworks ezahlukeneyo, kubandakanywa ii-angles zentsimbi, iziteshi zentsimbi, kunye nokunye.

-Honsen Magneticsumazibuthe wokuvala wakhiwe kusetyenziswa imagnethi ye-neodymium esisigxina. Ngokomgaqo, ukuba ubushushu obuphezulu bokusebenza buhlala bungaphantsi kwe-80 ° C kwaye imagnethi ayigcini umonakalo okanye i-corrosion, amandla okubambelela aya kuhlala ngonaphakade.

-Ufakelo luthe ngqo kwaye ukusebenza kusebenziseka lula.

-Inika ukuguquguquka kokukhetha izikhundla ezinqwenelekayo, ukunciphisa ixesha lofakelo.

- Ixabiso elisebenzayo, kunye nembuyekezo ekhawulezayo kutyalo-mali.

- Uyilo oluhlala ixesha elide luqinisekisa ubomi obude, luvumela ukusetyenziswa kwakhona.

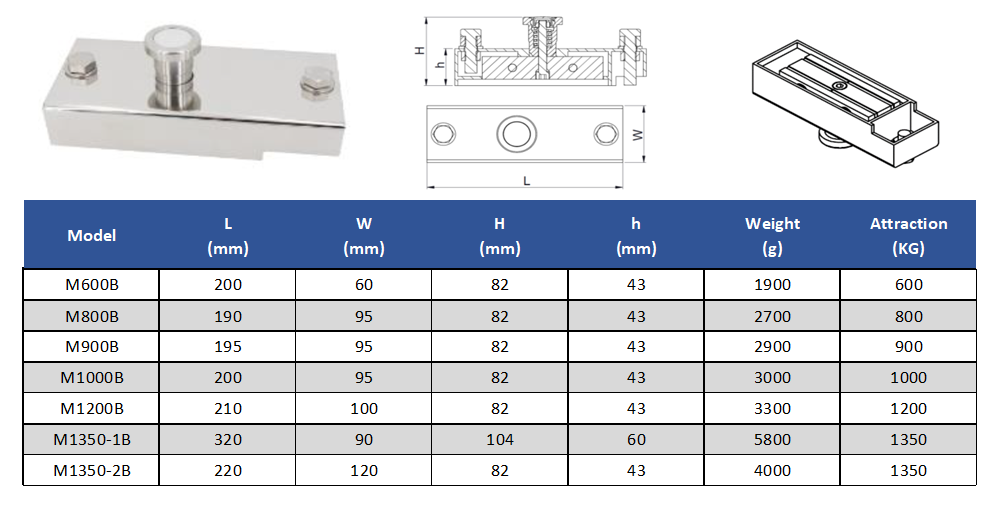

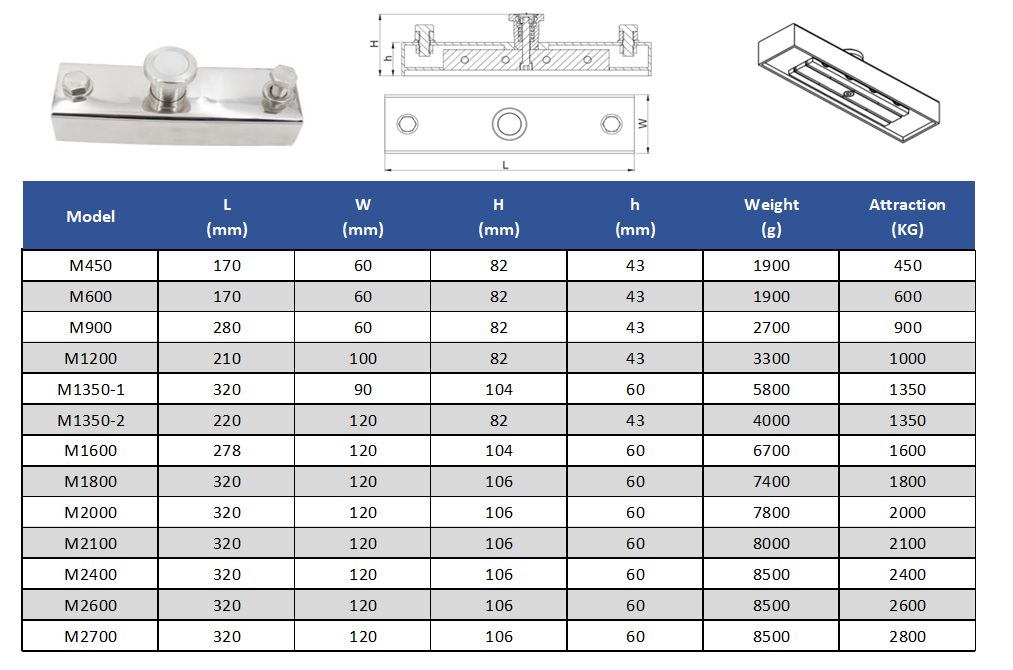

- Amandla ancamathelayo asuka450 KGS ukuya 3100 KGS,ukunika amandla okubamba awomeleleyo.

- Ukuphelisa imfuno ye-welding; amandla kazibuthe umazibuthe ayibambe ngokukhuselekileyo itemplate kwindawo.

-Iguquguquka kakhulu, umazibuthe omnye we-precast formwork unokusetyenziswa kunye neentlobo ezahlukeneyo zefomworks zekhonkrithi.

Kutheni kufuneka usebenzise iimagnethi zokuShuttering?

Iimagnethi zokuShutha zeFormwork ziye zaliguqula ishishini lekhonkrithi langaphambili, likhokelela kwinkqubela phambili emangalisayo! Jonga ezi nzuzo zilandelayo zokuzisebenzisa. Ngelixa sidwelise izizathu zokuba kutheni, kukhuselekile ukuthi izibonelelo zokuvala umazibuthe phantse azinamda.

- Ukulungeleka okungafaniyo kunye ne-70% yokuhamba ngokukhawuleza komsebenzi xa kuthelekiswa neendlela zendabuko.

-Khusela iitafile zakho zokufa kwiziphumo eziyingozi zokomba, ngaphandle kwesidingo se-welding, uqinisekise ubomi obude.

- Ukunciphisa iindleko zabasebenzi ngokubonakalayo ngokusetyenziswa kweemagnethi ezivalayo, okwenza umjikelo wokuhlawula ngokukhawuleza.

-Ukuguquguquka okumangalisayo kunye nokuguquguquka kwiimathiriyeli zeformwork ezahlukeneyo njengeplastiki, intsimbi, kunye nomthi.Usetyenziso olungenasiphelo olunokwenzeka kunye nokukhetha ukwenza iimagnethi zihlangabezane neemfuno zakho ezithile.

-Cima imfuneko yezixhobo ezininzi ezikhethekileyo, njengoko ezi magnethi zinamandla amangalisayo okuphakamisa ubude bebhodi kwaye uyiqinise ngokukhuselekileyo kwibhentshi yokusebenza yentsimbi.

- Yenzelwe ngokukodwa ukusetyenziswa okuthembekileyo kwizityalo zekhonkrithi, ukuqinisekisa uqhagamshelwano olungagungqiyo.

- Isisombululo esingabizi kakhulu sokwakha amacandelo.

-Uyilo olusebenziseka lula lomsebenzisi luvumela ukuba kube lula ukuchithwa kunye nokuhlanganisa.

- Ukukhuthaza ukuphinda kusetyenziswe ukubumba okubumbayo, okukhokelela kugcino lweendleko zexesha elide.

- Isebenza kuluhlu olubanzi lweemeko zokuvelisa, kubandakanywa zombini umntu kunye nemveliso enkulu yeemveliso zekhonkrithi kwiitafile zetsimbi.

- Linciphisa kakhulu ixesha elifunekayo lofakelo lweformwork.

-Imagnethi yetemplate eyenziwe ngokwezifiso ukuze ihlangabezane neemfuno ezahlukeneyo.

-Ukusebenza ngokungenamzamo ngokuma kwemagnethi okuchanekileyo.

- I-Versatile ehambelanayo, ifanelekile zombini iinkuni kunye ne-steel formwork.

-Iziqhayisa ngesakhono esiluqilima sokudibanisa ukumelana nomthwalo ukusuka450 KGS ukuya 3100 KGS.

- Ukukhusela iitafile zeformwork ngaphandle kwesidingo sokugrumba umphezulu, ukuwelda, okanye ukubholitha.

- Igcina ingqibelelo yomphezulu, ekhokelela kubomi obude.

-Inikezela ngemisebenzi emininzi ngemagnethi enye esebenzela iinjongo ezahlukeneyo.

-Imingxuma eyakhelwe-ngaphakathi edityanisiweyo edityanisiweyo ukulungiselela imilinganiselo eyahlukeneyo yeformwork.

- Ukwandisa imveliso kunye nomgangatho weendonga zekhonkrithi zangaphambili.

Honsen Magneticsibiphambili kwimveliso kunye nokubonelela ngeemagnethi ezisisigxina, izinto zemagneti, kunye namanqaku omagnetic ngaphezulu kweshumi leminyaka. Iqela lethu elinezakhono lilawula uluhlu olupheleleyo lwemisebenzi yokuvelisa ukusuka kwi-machining kunye nendibano ukuya kwi-welding kunye nenaliti yokubumba. Siyonwabela igama elihle eYurophu naseMelika, kwaye impumelelo yethu ibalelwa kwimveliso yethu ekumgangatho okhuphisanayo, kunye nokuzinikela kwethu ngamandla kwinkonzo egxile kubathengi.

- Engaphezulu kweI-10 iminyaka amava kwimveliso yemagnethi esisigxina

- Ngaphezulu5000m2 umzi-mveliso uxhotyiswe nge200Oomatshini abaphambili

- Yibaneumgca wemveliso opheleleyoukusuka kwi-machining, ukudibanisa, ukuwelda, ukubumba isitofu

- Yiba neqela eliqinileyo le-R&D linokubonelela ngokugqibeleleyoOEM & ODM inkonzo

-Abasebenzi abanezakhono & nokuphuculwa okuqhubekayo

- Thinakuphelaukuthumela ngaphandle iimveliso ezifanelekileyo kubathengi -

-Ukuthunyelwa ngokukhawuleza kunye nokuhanjiswa kwehlabathi jikelele

- KhonzaI-ONE-STOP-SOLUTION qinisekisa ukuthenga okusebenzayo kunye nexabiso eliphantsi

-Iiyure ezingama-24inkonzo ye-intanethi ngempendulo yokuqala

Injongo yethu ephambili kukubonelela abathengi bethu ngenkxaso ejonge phambili kunye nenguqu, iimveliso ezikhuphisanayo, ekugqibeleni siphucula indawo yethu yentengiso. Ngokuzibophelela kwethu kutshintsho lwetekhnoloji, sisukela ngamandla ukukhula kwaye sijonge iindlela ezintsha zokuthengisa ngempumelelo eyodwa kwiimagnethi ezisisigxina kunye namacandelo. Sikhokelwa yinjineli yethu eyintloko, isebe lethu le-R&D elinamava lixhasa ubuchwephesha bangaphakathi, likhulisa ubudlelwane obuluqilima babathengi, kwaye lilindele iintsingiselo zemarike. Amaqela azimeleyo ajongana neeprojekthi zehlabathi, eqinisekisa ukuba uphando luqhubeka luqhubela phambili.

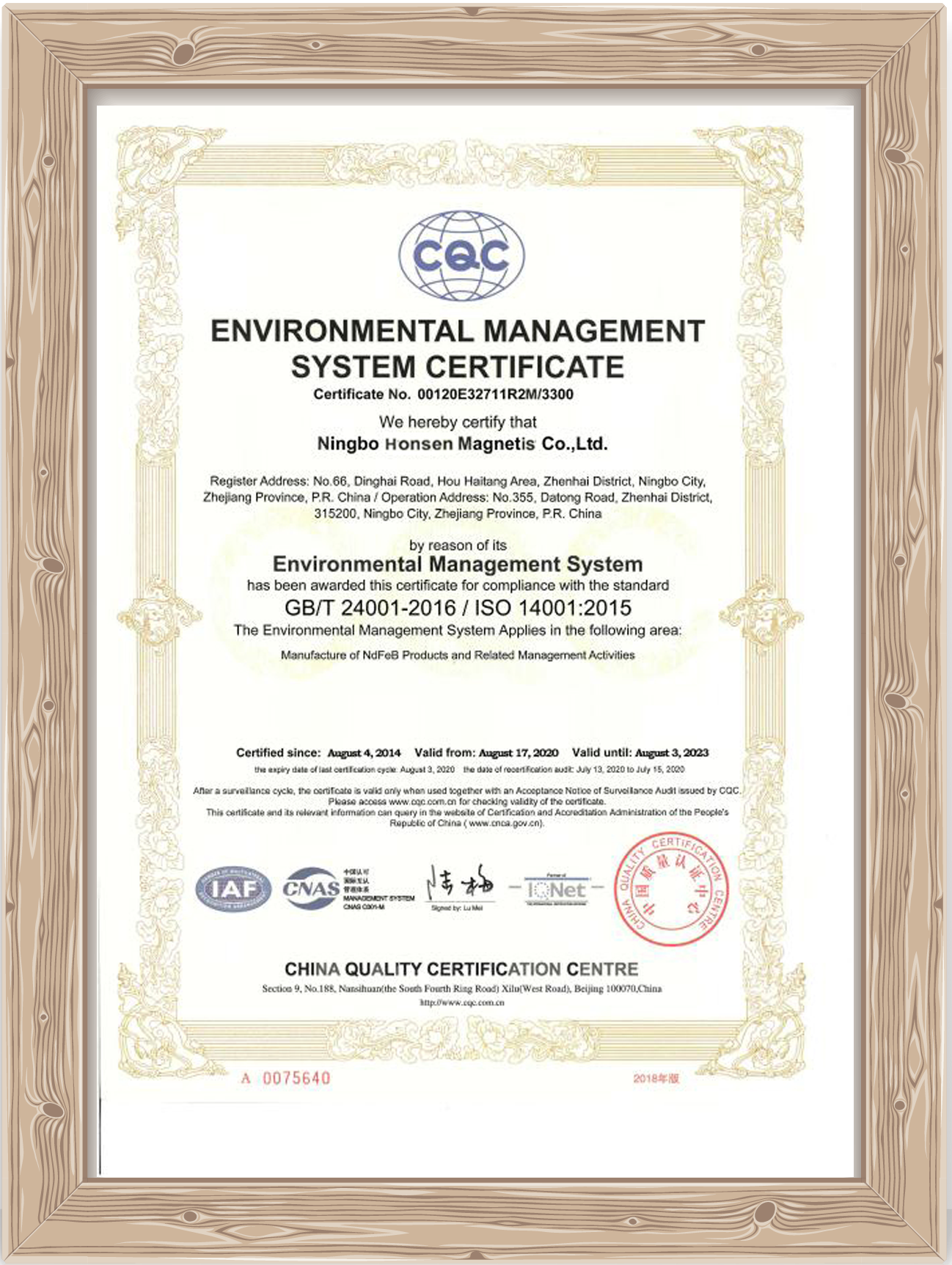

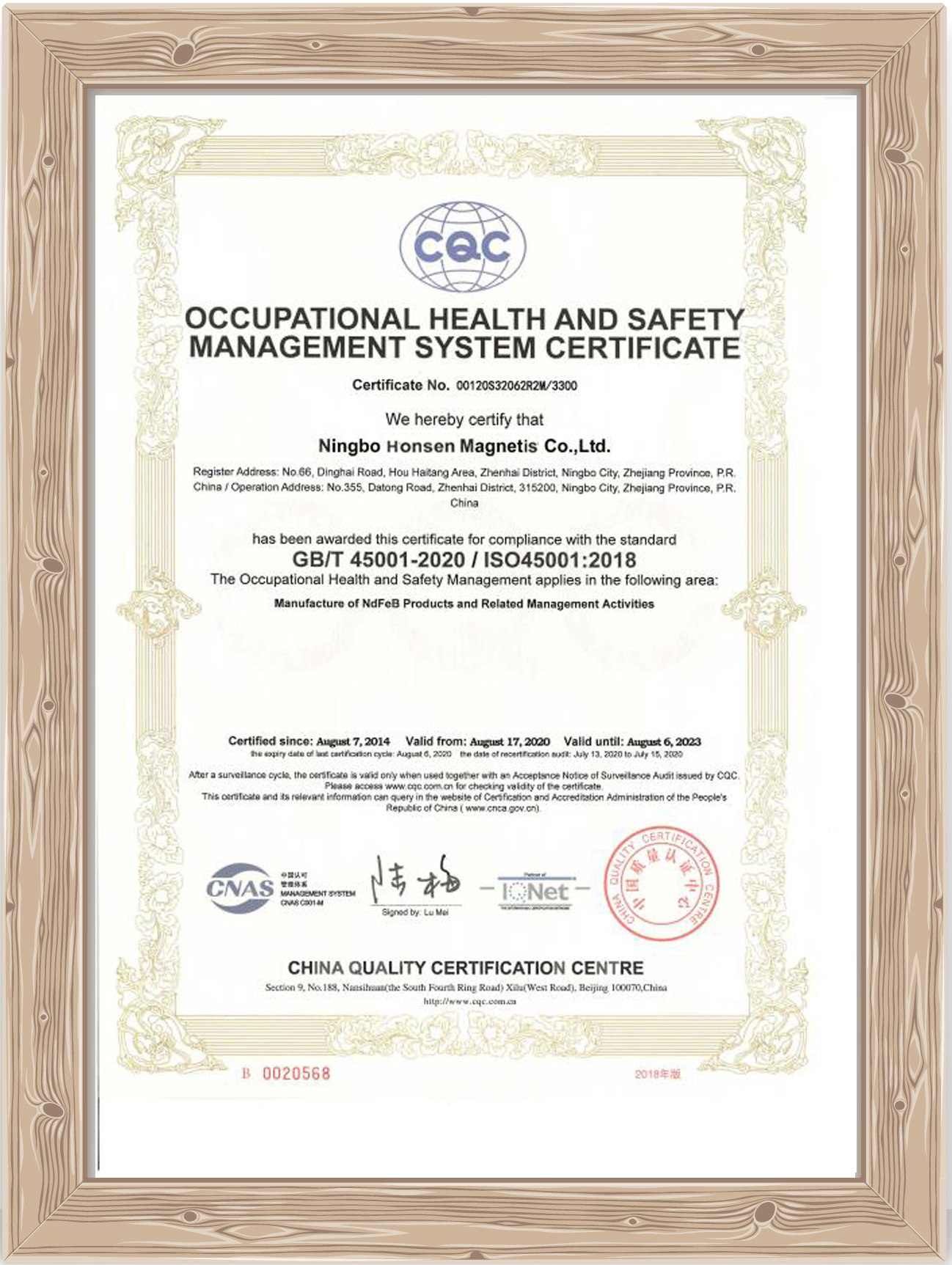

Ulawulo lomgangatho luzinze nzulu kwinkcubeko yethu yoshishino. Sithatha umgangatho njengeyona nto ingundoqo kunye namandla akhokelayo kwishishini. Ukuzinikela kwethu akugungqi - sidibanisa ngaphandle komthungo inkqubo yethu yolawulo lomgangatho kwimisebenzi yethu. Oku kuqinisekisa ukuba iimveliso zethu zihlala zidibana kwaye zigqithise ukulindela kwabathengi, kugxininisa ukuzibophelela kwethu okungaguqukiyo kumgangatho.

Honsen Magneticskufana nokugqwesa, okusekelwe ekubekeni phambili ukwaneliseka nokhuseleko lwabathengi. Ukuzinikela kwethu kuphuhliso olupheleleyo lwabantu bethu kuhambelana nale filosofi. Ngokukhulisa uhambo lomqeshwa ngamnye, sibeka isiseko sokukhula koshishino lwexesha elide.