Ukusetyenziswa kwemichilo yentsimbi yemagnethi isetyenziswe ngokubanzi kwishishini lekhonkrithi esele ibekwe amashumi eminyaka. Esi sixhobo somelele kakhulu senziwe ukuba simelane neemeko zokusebenza ezigqithisileyo kwaye sihlala sisetyenziselwa ukubamba ngokukhuselekileyo imiphezulu yentsimbi. Injongo yalo ephambili kukudala imiphetho edibeneyo kwiikona zekhonkrithi, kunye nezicelo ezithile zefom.

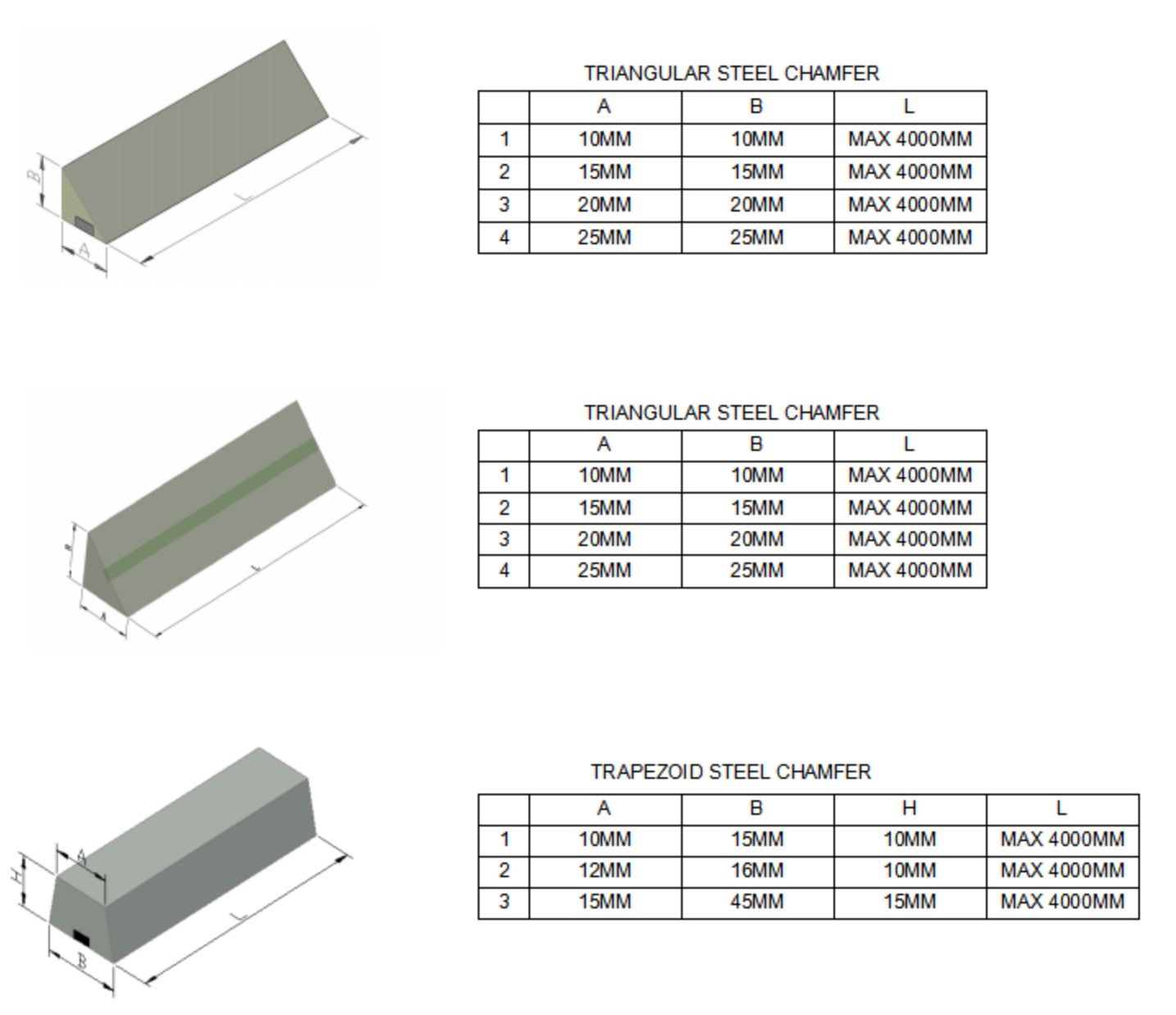

Eyona milo mibini ixhaphakileyo kwezi zintlu zemagnethi ngoonxantathu kunye neetrapezoid. Imichilo yemagnethi iye yaba yenye yezona zixhobo ziguquguqukayo kwishishini lekhonkrithi ye-precast. Abavelisi banokukhetha kwiindidi ezahlukeneyo zobukhulu kwaye banokukhetha ukwenza ngokwezifiso imicu ukuze bahlangabezane neemfuno zabo ezithile. Ukuguquguquka kwale micu kwandisa ukuhambelana kwazo kunye nezakhiwo ezahlukeneyo zekhonkrithi, ziqinisekisa uluhlu olubanzi lwezicelo. Ukongeza kumsebenzi wayo, imichilo yentsimbi yemagnethi ikwanezibonelelo ezahlukeneyo.

Okokuqala, banikezela ngokubambelela ngokuqinileyo ngenxa yeempawu zabo zamagnetic, okubangela uxhulumaniso oluqinileyo phakathi kweendawo eziphathekayo kunye nentsimbi. Okwesibini, ezi ziqwenga zibonelela ngeendleko kunye nexesha elifanelekileyo. Inkqubo yabo yokufakela kunye nokususa elula igcina ixesha elixabisekileyo ngexesha lokwakha, ngaloo ndlela inciphisa iindleko zabasebenzi.

Ukongezelela, indalo yabo enokuphinda isebenziseke isusa imfuno yokutshintshwa ngamaxesha athile, ukonga iindleko zexesha elide. Enye inkalo ephawulekayo yale micu yamagnetic kukuhambelana kwayo noyilo olwahlukileyo lolwakhiwo. Zidibanisa ngokungenamthungo kwizakhiwo ezahlukeneyo zekhonkrithi, ziphucula ubuhle bemveliso yokugqibela.

Le micu iqinisekisa imiphetho echanekileyo kunye nechamfered echanekileyo yokugqitywa okupholisiweyo kunye nobungcali. Imichilo yentsimbi yemagnethi idlala indima ebalulekileyo ekuqinisekiseni imfezeko yolwakhiwo lweziqalelo zekonkrithi zangaphambili. Ngokwenza imiphetho ye-beveled, banciphisa umngcipheko wokutshiza kwaye banikeze ukuchasana kwempembelelo enkulu. Oku kwandisa ukuqina kunye nobomi obude besakhiwo sekhonkrithi ye-precast, iqinisekisa ukuzinza kwayo kunye nokusebenza kwayo kwiminyaka ezayo.

Umcu wokuchama intsimbi yemagnethi uye waba yinto eyimfuneko kushishino lwekhonkrithi yangaphambili. Ukukwazi kwabo ukumelana neemeko ezigqithisileyo, ukuguquguquka kwabo ngobukhulu kunye nokwenza ngokwezifiso, kunye neenzuzo zabo ezininzi zibenza babe yinxalenye ebalulekileyo yokwakhiwa kwezakhiwo zekonkrithi ezikumgangatho ophezulu. Ngokubambelela ngokuqinileyo, iindleko kunye nexesha elifanelekileyo, ukuhambelana noyilo lwezakhiwo, kunye negalelo kwingqibelelo yesakhiwo, le micu yamagnetic iyaqhubeka idlala indima ebalulekileyo kwishishini lokwakha.

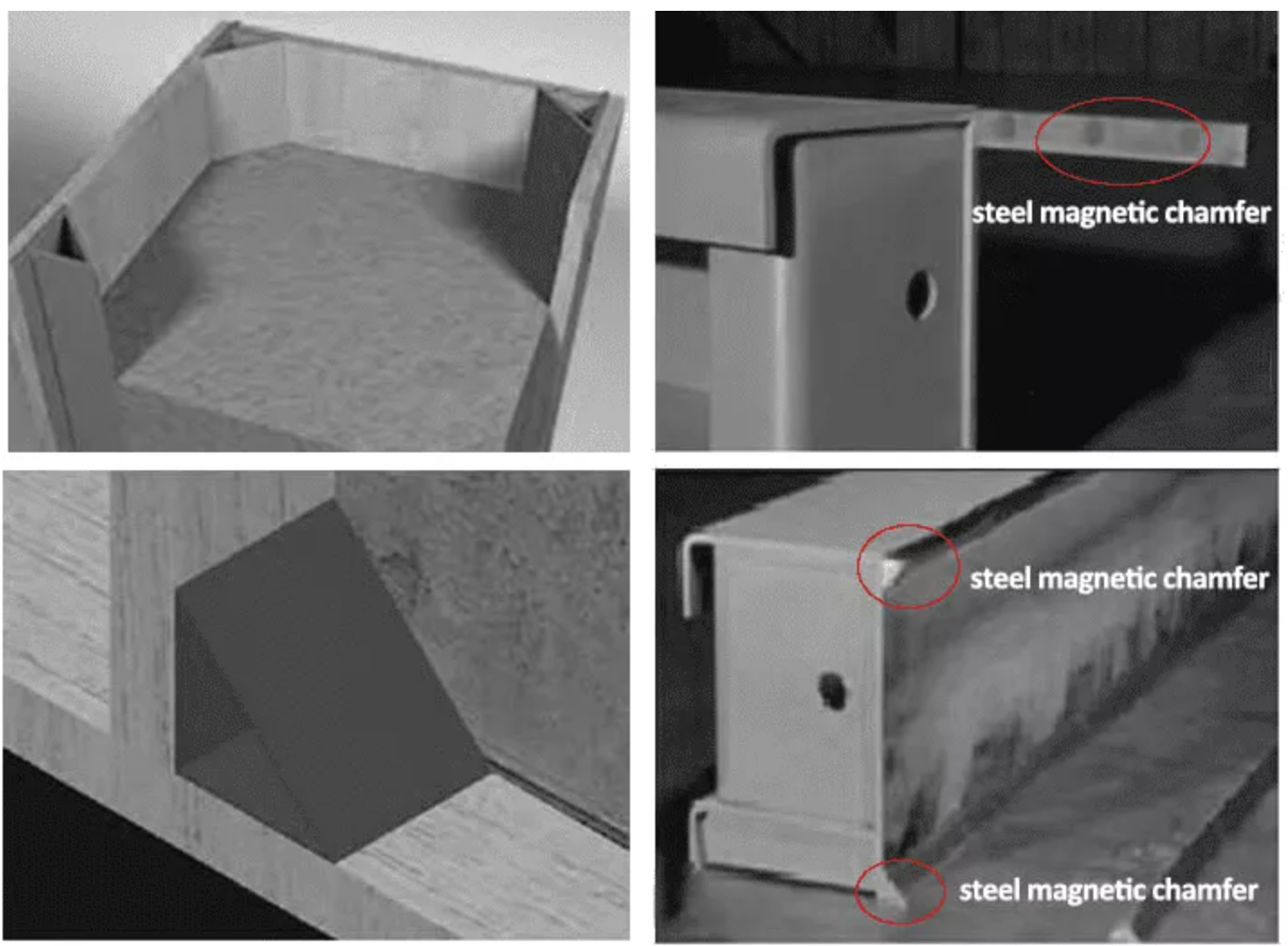

Khetha ii-chamfers ezinecala elinye xa ujoyina intsimbi enye ngexesha, njengeetafile zentsimbi okanye iipaneli. Xa usebenza ngamacandelo amabini ensimbi akufuphi, khetha i-chamfering emacala amabini ukuqinisekisa ukubekwa okukhuselekileyo kweendawo zombini.

Material: Irabha, Q215, Q235 Iron Parts, Neodymium Magnets

Unyango loMphezulu: IMagnet Zn okanye iNiCuNi Coating

Ubushushu bokusebenza obuninzi: 80℃

Ukusebenziseka kwakhona kunye nokuqina okuhlala ixesha elide;

Izinto zemagneti ezifakwe ngentsimbi zibonelela ngokuncamathela okuphezulu kakhulu;

Ukuphucula isivuno kunye nomgangatho weendonga zekhonkrithi zangaphambili Ukuphatha ngokulula ngaphandle kokutsalwa kwemagnethi ngexesha lokusetyenziswa kwesiqhelo;

Ukuphelisa imisele efuna ukuzaliswa kwekhonkrithi;

Ukumisa ngokukhawuleza kunye nokulula, ukususwa kunye nokucoca Ukubekwa ngokuchanekileyo kwifomwork ngaphandle kwezikrufu, iibholiti okanye i-welding, ukuphepha nawuphi na umonakalo kwitafile yefom;

Yenzelwe ukuba ilingane ngokungenamthungo kunye neebhedi zentsimbi, iipaneli zentsimbi kunye nazo zonke iintlobo zeefreyimu ze-precast kaloliwe;

Xa kuthelekiswa neepali zesiqhelo zokurhangqa, ukufunxa okunamandla kuqinisekisa ukuba iipali ezitsalayo aziyi kuhamba ngexesha lokunkcenkceshela;

Ukwandiswa okulula, ukulinganisa kunye nokuveliswa kobuninzi.

- Ngelixa ukufunxa kwemichilo ye-chamfer kungenamandla njengaleyo yeemagnethi zetemplate, isenayo isixa esifanelekileyo sokufunxa. Ukusetyenziswa kakubi kunokubangela ukwenzakala komntu, umonakalo kwimagnethi, okanye umonakalo kwindawo yokusebenza. Ngelixa ii-chamfers zethu zentsimbi ezinobuchwephesha zisebenziseka ngokulula, ukuthatha amanyathelo okhuseleko ambalwa akuyi kukukhusela kuphela kodwa i-chamfer ngokwayo. Ngezantsi, sichaza iingcebiso zokhuseleko ngaphambi, ngexesha, nasemva kokusetyenziswa.

Kuphephe ukubeka i-chamfer ngokuthe nkqo njengoko amandla empembelelo anokwaphula umazibuthe. Endaweni yoko, beka intonga ye-chamfer kwelinye icala kuqala, uze uyibeke ngobumnene endaweni.

- Nangona iimagnethi kunye nentsimbi ziphathwa ukukhusela umhlwa, ukunqongophala okungapheliyo kokucoca kunokubangela ukuba i-samente ibambelele kwimicu ye-chamfer, okwenza kube nzima ukuyisusa. Ukwandisa ubomi be-chamfer yakho, yicoce emva kokusetyenziswa ngalunye kwaye usebenzise ioli echasene ne-rust ukuze uyigcine ikwimeko ephezulu yokusebenza.

- Qinisekisa ukuba ubushushu bokusebenza okanye ugcino buhlala bungaphantsi kwama-80°C. Amaqondo obushushu aphakamileyo anokubangela ukuba imicu ye-chamfer ibe buthathaka okanye ilahlekelwe ngokupheleleyo yimagnethi.

-Yigcine kude nezixhobo zombane (ezifana neeselfowuni, iilaptops, iitafile kunye neekhompyuter) kunye neentsimbi ezingeyomfuneko ze-ferromagnetic.

-Sebenzisa ngononophelo olukhulu xa usebenzisa ii-chamfers kufutshane nabantu abane-pacemakers. I-chamfer yentsimbi engunxantathu idala indawo enozibuthe eyomeleleyo enokuphazamisana nezinto ze-elektroniki ezingaphakathi kwe-pacemaker.

- Ukuba nayiphi na ikhonkrithi okanye i-debris ibambelele kwi-chamfer, yisuse ngokukhawuleza. Kwiidiphozithi zekhonkrithi ezinenkani, zikhuhle ngobunono okanye uzipolishe.

- Soloko ugcine umphezulu wetafile yokungunda ugudile. Ukuba kukho into eqinileyo phakathi kwemagnethi kunye netafile yokungunda, ukufunxa okunamandla kunokubangela ukuba umazibuthe enze ukonakala.

- Soloko uzibambe ngenkathalo iichamfers ezinxantathu. Xa ugqibile, beka kancinci ukunqanda ukukhubeka okanye ukucinezela izandla neminwe ngempazamo.

- Sincoma ukugcina ii-chamfers kwiplasitiki okanye i-rubber stand ukuqinisekisa ukufikelela lula.

Kuphephe ukuba sesichengeni ixesha elide kukukhanya kwelanga njengoko amaqondo obushushu aphezulu anokubangela ukuba buthathaka kwemagnetism okanye ukuphelisa ngokupheleleyo imagnethi chamfers.

- Gcina imiphezulu icocekile. Nangona zombini umazibuthe kunye nentsimbi ziphathwa ukuthintela umhlwa, ukusilela ukucoca umazibuthe ngokufanelekileyo kunokubangela ukuba isamente ibambelele kumcu we-chamfer, kube nzima ukuyisusa. Ke ngoko, abasebenzisi bayacetyiswa ngamandla ukuba bacoce kwaye bathambise emva kokusetyenziswa ngakunye. Nangona i-rust-resistant-resistant kwimigangatho yentsimbi, ikhonkrithi i-alkaline kunye ne-corrosion, enokubangela ukubola kwimigangatho yentsimbi ngokuhamba kwexesha.

Yasekwa kwiminyaka elishumi eyadlulayo,Honsen Magneticsligama elaziwayo kwicandelo lemagnethi esisigxina kunye nezixhobo zokuvelisa kunye nokuthengisa. Iqela lethu elinamava longamela wonke umjikelo wemveliso, kubandakanywa umatshini, ukudibanisa, ukuwelda, kunye nokubumba inaliti. Iimveliso zethu zithandwa phesheya ngakumbi eYurophu naseMelika ngenxa yamaxabiso azo akhuphisanayo, umgangatho obalaseleyo, kunye nokuzinikela kwethu okungagungqiyo kwinkonzo yomthengi.

- Engaphezulu kweI-10 iminyaka amava kwimveliso yemagnethi esisigxina

- Ngaphezulu5000m2 umzi-mveliso uxhotyiswe nge200Oomatshini abaphambili

- Yibaneumgca wemveliso opheleleyoukusuka kwi-machining, ukudibanisa, ukuwelda, ukubumba isitofu

- Yiba neqela eliqinileyo le-R&D linokubonelela ngokugqibeleleyoOEM & ODM inkonzo

-Abasebenzi abanezakhono & nokuphuculwa okuqhubekayo

-Ukuthunyelwa ngokukhawuleza kunye nokuhanjiswa kwehlabathi jikelele

- KhonzaI-ONE-STOP-SOLUTION qinisekisa ukuthenga okusebenzayo kunye nexabiso eliphantsi

-Sebenza nabathengi abakhulu kunye nabancincingaphandle kwe-MOQ

Sizimisele ukubonelela ngoncedo olujonge phambili kunye noyilo, iimveliso ezikhuphisanayo, kwaye injongo yethu kukuqinisa indawo yethu yentengiso. Siqhutywa yinkqubela phambili ebalulekileyo kwimagnethi esisigxina kunye namacandelo, sigxile ekukhuleni ngokuphumelela kwetekhnoloji kunye nokungena kwiimarike ezintsha. Ikhokelwa yiNjineli eyiNtloko, isebe lethu le-R&D elinezakhono lisebenzisa amandla angaphakathi, likhulisa ubudlelwane babathengi, kwaye lilindele iintsingiselo zentengiso ngokubona kwangaphambili. Amaqela azimeleyo alawula ngononophelo iiprojekthi zamazwe ngamazwe kwaye agcine umjelo ozinzileyo womsebenzi wophando.

Ulawulo lomgangatho kusembindini wefilosofi yethu yoshishino. Sithatha umgangatho njengowona mandla kunye nomgaqo okhokelayo wenkampani. Ukuhamba ngaphaya kwamaxwebhu nje, sidibanisa ngaphandle komthungo inkqubo yethu yolawulo lomgangatho kwiinkqubo zethu. Oku kuqinisekisa ukuba iimveliso zethu zihlala zihlangabezana kwaye zogqitha iimfuno zabathengi bethu, nto leyo ebonisa ukuzibophelela kwethu kumgangatho wokugqwesa.

At Honsen Magnetics, imigaqo yethu engundoqo iphindwe kabini: ukuqinisekisa amava akhethekileyo omthengi kunye nokugcina ibhenchmark yokhuseleko olungagungqiyo. Le migaqo isebenza kumalungu eqela lethu kwaye ixhasa uphuhliso lomntu. Ukukhula komsebenzi ngamnye kukhuthaza inkqubela phambili eqhubekayo yeshishini lethu.