Precast Concrete Formwork Magnets

Iimagnethi ze-Concrete Precast(i-PC yokulungisa izixhobo zemagneti) zizixhobo eziyimfuneko ezisetyenziswa kwiindlela ezahlukeneyo zokwakha.IiNkqubo zeFormwork yeConcrete yePrecastzisetyenziselwa ukukhusela ifom yecala kunye nezinto ezifakwe kwiinkqubo zekhonkrithi zangaphambili.I-Precast Concrete Systems iqinisekisaUkuphathwa ngokufanelekileyo kunye nokukhuselekileyo kwezinto eziphathekayo, okubangelwa ukwakhiwa okukhawulezayo kunye nokuchaneka ngakumbi.Iinkqubo ze-Concrete ze-Precastlolunye uphuhliso lwangoku lokwakhiwa kwemizi-mveliso, kwaye iqashwe kakhulu kumacandelo okwakha, ezothutho, ukongiwa kwamanzi, uloliwe ohamba ngesantya esiphezulu, ukwakhiwa kweendlela, njalo njalo.

Inzuzo ephambili yokusebenzisaIimagnethi ze-Concrete Precastkukuguquguquka kwazo. Zingasetyenziselwa kwiindidi ezahlukeneyo zokwakha iifom, kubandakanywa iindonga, iikholomu, imiqadi, kunye namacwecwe. Nokuba yeyiphi imilo okanye ubungakanani bento ekhonkrithi, ezi magnethi zibonelela ngamandla ombane athembekileyo nawomeleleyo ukuze azibambe ziqine endaweni. Kwaye i-Precast Concrete Formwork Magnets kulula kakhulu ukuyisebenzisa. Ziyilwe ngendlela elula, kodwa esebenzayo, evumela ukufakela kunye nokususwa okukhawulezayo kunye nokungasebenzi.

Ngaphandle kwamandla abo kunye nokusebenziseka ngokulula,Iimagnethi ze-Concrete Precastzikwabonelela ngokuqina kunye nobomi obude. Zenziwe ngeiimagnethi ze-neodymium, okuqinisekisa amandla amagnetic aqhubekayo nakwiimeko ezinzima. Ezi magnethi ze-NdFeB zinokumelana nobushushu obugqithisileyo, iikhemikhali, kunye nokufuma, zizenza zilungele zombini iiprojekthi zokwakha zangaphakathi nangaphandle.

Iingenelo zokusebenzisa iimagnethi zeConcrete zePrecast

- Ukunciphisa kakhulu iindleko zabasebenzi kunye nezinto eziphathekayo kunye nokuphucula kakhulu ukufakela kakuhle;

- Ukubekwa okulula kunye nokuchanekileyo;

- Akukho sidingo sokusebenzisa izikrufu, iibholiti, okanye i-welding yokubeka indawo, enokuthintela umonakalo kwitafile yokubumba ngowona mlinganiselo mkhulu;

-Ukusetyenziswa kwakhona, ubomi benkonzo ende kunye nembuyekezo emfutshane kutyalo-mali;

- Ubume bendawo yokwakha kunye nokhuseleko lwabasebenzi bokwakha kunokuphuculwa kakhulu.

Iimagnethi ze-Concrete Precastzisetyenziswa ngokuqhelekileyo njengesixhobo sokulungisa ukuqiniswa kwesiseko okanye iikholomu ngexesha lokwakhiwa kweepali kunye neentsika kulwakhiwo oluqhelekileyo. Kwishishini lokwakhiwa kwangaphambili, xa kwakhiwa i-formwork, ukuqiniswa akukwazi ukuthungwa ngokuthe ngqo kwi-formwork, kuba kuya kubangela ukuba i-formwork ikhule ibe yi-concave shape emva kokumisa, okuya kukhokelela ekuphambukeni phakathi kweyona milo ye-formwork kunye nekhonkrithi. udonga.Iimagnethi ze-Concrete PrecastZizibambi zemagnethi ezinkulu ezinamandla ezinemijikelezo yamagnetic ekhethekileyo, umhlaba wemagnethi oveliswa yiI-Precast Concrete Magnetyomelele kakhulu, ngoko ke zimbiniIimagnethi ze-Concrete Precastiposwe kuzo zombini iziphelo zokuqiniswa kunokulungisa ngokuqinileyo i-formwork.

Honsen Magneticsuyazingca ngokuzibophelela kwethu ekunikezeleni umgangatho ophezulu kunye nokugqwesa kobugcisa. Ngezixhobo zethu zokuvelisa eziphambili, siyakwazi ukwenza uluhlu olubanzi lwe-Precast Concrete Formwork Systems. Iqela lethu elizinikeleyo leengcali, elixhotyiswe ngezixhobo zokuvavanya ezichanekileyo, liqinisekisa ukuba iimveliso zethu zihlangabezana nemigangatho ephezulu.

1. Ukuvala iimagnethi

Ukuvala iimagnethizizixhobo zoguqulo ezisetyenziswa kushishino lwekhonkrithi ye-precast. Banikezela ngendlela ekhawulezayo nesebenzayo yokukhusela i-formwork kwiibhedi zokugalela ngentsimbi ngaphandle kwesidingo sokomba, ukuwelda, okanye ukukrwela. Umazibuthe wetemplate uneyunithi yemagnethi yeNdFeB etshintshekayo, indlu enebhloko yemagnethi, kunye nezikrufu zokulungisa. Ngokudityaniswa kweemagnethi ze-neodymium kunye neepleyiti zentsimbi, isekethe yemagnethi enamandla yenziwa ukuvelisa umtsalane onamandla. La mandla asebenza ukubamba iinkuni okanye i-formwork yentsimbi endaweni. Amaqhosha okulawula abekwe phezu kweemagnethi zekhonkrithi esele zikho. Xa iqhosha licinezelwe, umazibuthe ubamba isiphaluka samagnetic, ubambe itemplate ngokuqinileyo kwipleyiti yentsimbi. Endaweni yoko, iqhosha lokucima liququzelela ukubekwa kwakhona kwemagnethi ngokulula. Kukho imingxunya emibini ephothiweyo jikelele kumphezulu wemagnethi yetemplate, eyilelwe ukuthwala iiadaptha ezahlukeneyo. Iimagnethi zokuShuttering ukusukaHonsen Magneticsinokwenziwa ngokweemfuno zakho ezithile, ngaloo ndlela ibonelela ngamava osetyenziso olwahlukeneyo.

2. Iinkqubo zokuvala imagnethi

Iinkqubo zokuvala, kwaziwa njengeIiNkqubo zeFormwork, zibalulekile kushishino lokwakha ukuze kubonelelwe ngenkxaso efunekayo kunye nesiqulatho sekonkile esandul' ukugalelwa. Ngokukhetha iiNkqubo zethu zokuShuttering, ukhetha isisombululo esithembekileyo nesisebenzayo sokuxhasa ngokufanelekileyo kwaye uqulathe ikhonkrithi esandula kugalelwa. Uluhlu lwethu lweeNkqubo zokuShuttering luyilwe ngononophelo ukuhlangabezana neemfuno ezahlukeneyo zeeprojekthi zokwakha ezahlukeneyo. Nokuba luphuhliso lwendawo yokuhlala encinci okanye lushishino olukhulu, iinkqubo zethu zisebenza ngeendlela ezininzi kwaye zilungele ukujongana neemfuno ezithile zeprojekthi nganye.

At Honsen Magnetics, sibeka phambili umgangatho kunye nokuqina kweeNkqubo zethu zokuShuttering. Icandelo ngalinye lenziwa kusetyenziswa umgangatho ophezuluNdFeB Magnets, ukuqinisekisa ukomelela kunye nokumelana neemeko ezinyanzelisayo zeendawo zokwakha. Siyakwazi ukufumana uyilo olwenziwe ngokwethungi kubathengi.

3. Faka iimagnethi

Faka iimagnethi, kwaziwa njengeIimagnethi ezinemisonto yokuThwaza or I-Bushing Fixing Magnets, eyenzelwe ngokukodwa ikhonkrithi, idlala indima ebalulekileyo kwiinkqubo zokuvala imagnethi. Bakhonza injongo yokuqinisa ngokukhuselekileyo amacandelo ahlukeneyo kunye nokudala indawo yefom ngexesha lokuveliswa kweemveliso zekhonkrithi ezomeleziweyo. Ngokuguquguquka kwazo, ezi magnethi zifumaneka ngobukhulu obahlukeneyo, ngokufanelekileyo ukunciphisa iindleko zabasebenzi kunye nokuphucula ngokuphawulekayo umgangatho kunye nokusebenza kakuhle kweemveliso zokugqibela. Iimagnethi zokulungisa ezifakwe ngaphakathi ziqeshwe ngokubambisana ne-magnet formwork system okanye iitafile zentsimbi ngexesha lokwenziwa kwezakhiwo zekhonkrithi. Esi sixhobo sinamandla senze abavelisi bekhonkrithi be-precast balungelelanisa imisebenzi yabo yemihla ngemihla, okukhokelela ekugcinweni kwexesha kunye neendleko.Honsen Magneticsibonisa ukuzibophelela kwethu ekwenzeni izinto ezintsha kunye nokwaneliseka kwabathengi. Iqela lethu leengcaphephe lizinikezele ekuboneleleni ngeemveliso ezikumgangatho ophezulu ukuhlangabezana neemfuno ezihlala zitshintsha kushishino lokwakha.

4. I-Magnetic Chamfer

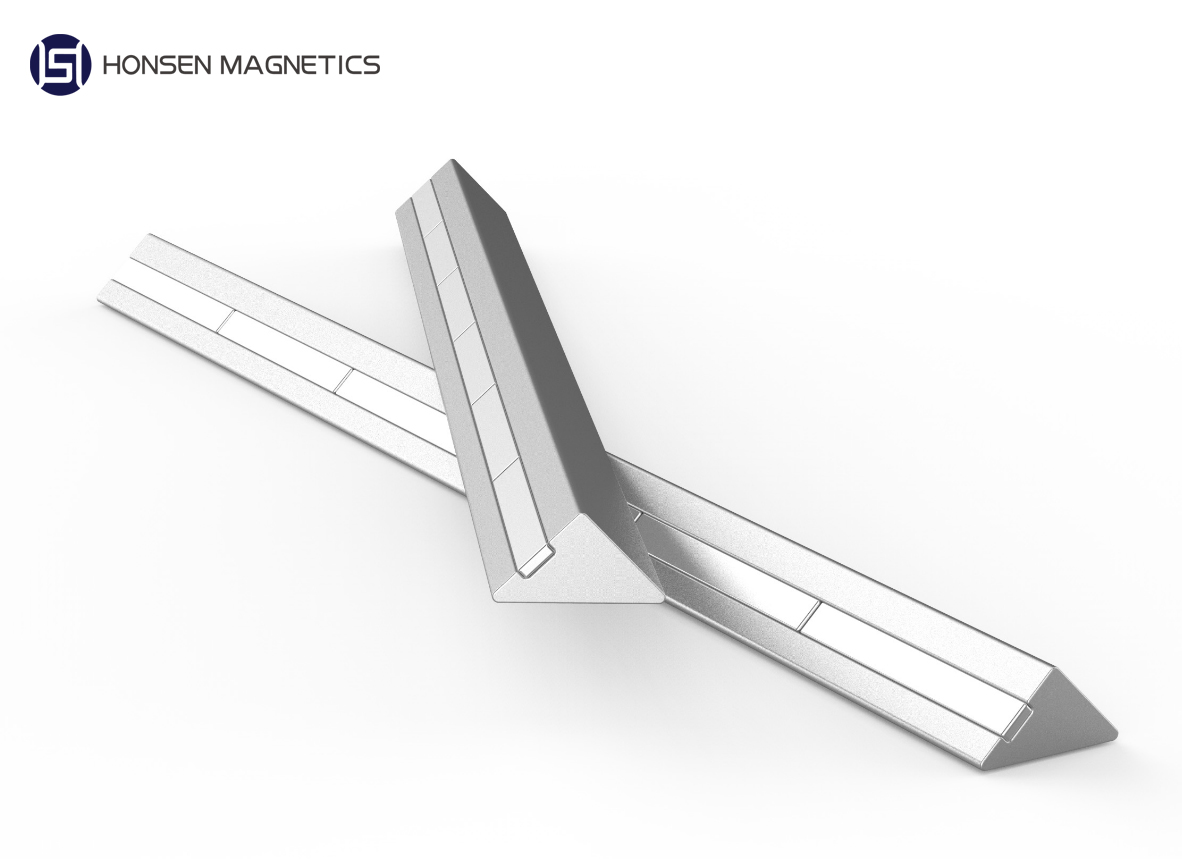

Kwiminyaka emininzi,Iintambo zeMagnetic Chamferbadlale indima ebalulekileyo kushishino lwekhonkrithi yeprecast. Zomelele kakhulu kwaye ziyakwazi ukumelana neemeko zokusebenza ezinzima. Ngokuyintloko baqeshwa ukuba baqhoboshele imiphezulu yentsimbi ngokukhuselekileyo.

Injongo yabo ephambili kukudala imiphetho edibeneyo kwiipaneli zodonga lwekhonkrithi kunye nefomwork. Unxantathu kunye neemilo zetrapezoid lolona yilo luqhelekileyo olusetyenziswayo kwezi zintlu zemagnethi. Ngokumalunga nokuguquguquka kwezinto, iintambo zemagneti zekhonkrithi ye-precast zizixhobo ezingenakulinganiswa kwishishini.

AtHonsen Magnetics, sinobukhulu obahlukeneyo esinokukhetha kubo kwaye sinokwenza ngokwezifiso ngokweemfuno ezithile zabathengi bethu.

5. Iadaptha yeemagnethi yokuvala

YethuUkuvala iAdapter yeemagnethiyenzelwe ngokukodwa ukusebenza ngokungenamthungo kunye nathiUkuvala iimagnethi. Ibonelela ngendlela ekhawulezayo nesebenzayo yokukhusela iifestile kunye neengcango zocango, izivalo zokhuni, izinto zokumisa ikhonkrithi yefiber, kunye nezinye izinto zokuvala. Sikwabonelela ngeenkonzo zesiko apho sinokuvelisa iiadaptha ukuhambelana neenkcukacha zakho ngqo.

Xa usebenzisa iimagnethi zethu zokuShuttering, iadaptha yethu iqinisekisa amandla aphezulu kunye nokuqina okuhle. Uyilo olukhethekileyo lwamazinyo olunqamlekileyo luvumela ukudibanisa ngokusondeleyo kunye ne-magnetic chuck, ukudala ukudibanisa okuqinileyo. Kuthetha ukuba naphantsi kwamandla angaphandle, akuyi kubakho zithuba okanye ukukhulula, okukhokelela kumgangatho ofanelekileyo webhodi yodonga yekhonkrithi yokugqibela. Njengoko ishishini lokwakha likhula ngokukhawuleza lisiya kushishino, sizimisele ukwenza nzulu unxibelelwano lwethu nomthengi ngamnye. Sijonge ukuphuhlisa nokuvelisa iimveliso ezikumgangatho ophezulu ezihlangabezana neemfuno eziphathekayo zemarike yasekhaya. Ngokwenza oko, sinethemba lokufaka igalelo kwizakhono zethu kunye neenzame kwikhonkco loshishino lolwakhiwo.

6. Ii-ankile zePin zokuPhakamisa

II-Pin yokuPhakamisa iiankile, ekwabizwa ngokuba yiDog Bone, isebenza njengenxalenye ebalulekileyo efakwe ngaphakathi kweendonga zekhonkrithi esele ibekwe ngaphambili. Injongo yayo ephambili kukuququzelela ukuphakamisa lula ngexesha lokwakha. Xa kuthelekiswa neendlela zentsimbi zokunyusela iintambo zentsimbi, ii-ankile zokuphakamisa ii-ankile ziye zafumana ukuthandwa ngokubanzi eYurophu, eMelika, naseAsia ngenxa yeenzuzo zazo ezininzi, kubandakanya ukusebenza kakuhle kweendleko, isantya, kunye nokonga iindleko zabasebenzi.

Sisebenzisa ubuchule bokubumba obubandayo okanye obushushu, sisebenzisa intsimbi eyi-20Mn2 njengesiseko semathiriyeli. Umphezulu wee-ankile ugqunywe okanye uhlanganiswe, uqinisekisa ukuba uhlangabezana neemfuno ezithile kunye neemfuno zabathengi. Njengoko umzi-mveliso wekhonkrithi we-precast uqhubeka nokuvela, ukuphakamisa iiankile ze-pin kuye kwaba yinxalenye yenkqubo, esebenza ngokubambisana nokuphakamisa ii-clutch kunye nee-recess zamathambo enja.

Kutheni Khetha Thina?

Honsen Magneticsigxile kwimveliso yePrecast Concrete Formwork Magnets. Iqela lethu libandakanya iinjineli zoyilo lwesekethe yemagnethi enobuchule kunye neenjineli zoyilo lomatshini ezizisa ubuchule bazo kuyo yonke iprojekthi. Ngeminyaka yamava kushishino, sakhe iqela eliqolileyo elinobuchule kuyilo, iisampulu, kunye nokuhanjiswa kweodolo yebhetshi.

Ukongeza kuyilo lwethu olubanzi kunye neenkonzo zemveliso, sigxininisa ukubaluleka kokuhambelana kwiimveliso zethu zebhetshi. Injongo yethu kukuphucula ngokuqhubekayo iinkqubo zethu zokuvelisa kunye nokunciphisa ukuphazamiseka kwabantu, ukuqinisekisa umgangatho ongaguqukiyo kunye nokusebenza kwibhetshi nganye. Sifezekisa oku ngokusebenzisa imilinganiselo engqongqo yokulawula umgangatho kunye noqeqesho oluqhubekayo kubasebenzi bethu abanamava emveliso.

At Honsen Magnetics, sizama ukubonelela ngenkonzo yokumisa enye, ukusuka kuyilo lokuqala ukuya kwimveliso yesampuli kunye nokuhanjiswa kwe-batch yokugqibela. Ngokudibanisa ubuchule bethu bobuchwephesha kunye nokuzinikela ekungaguqukiyo, sijolise ekuhambiseni umgangatho ophezulu wemagnethi ye-concrete formwork ehlangabezana neemfuno ezizodwa zabathengi bethu.

Iingenelo zethu kwimveliso ye-Precast Concrete Formwork Magnets:

- Iinjineli zoomatshini zibalulekile kwiqela, kunye neempawu zomatshini, ukunyamezelwa kwe-dimensional, kunye nezinye iinkalo zamacandelo magnetic ziyilwe kwaye zihlaziywe ngabo. Kananjalo baya kuphuhlisa esona sicwangciso sifanelekileyo sokusetyenzwa ngokusekwe kwimithombo yomatshini womatshini.

- Ukusukela ukuhambelana kwemveliso. Kukho iintlobo ezahlukeneyo zamacandelo magnetic kunye neenkqubo ezinzima, ezifana ne-gluing kunye nenkqubo ye-welding. I-gluing ye-Manual inokwahluka kumntu nomntu, kwaye ubuninzi beglue alikwazi ukulawulwa. Oomatshini bokusasaza ngokuzenzekelayo kwimarike abanako ukuziqhelanisa neemveliso zethu. Ke ngoko, siyile kwaye savelisa inkqubo yokuhambisa yolawulo oluzenzekelayo ukuphelisa izinto zabantu.

- Abasebenzi abanezakhono kunye nokuphuculwa okuqhubekayo! Ukuhlanganiswa kwamacandelo omagnetic kufuna abasebenzi abanezakhono zokuhlanganisa. Siye sayila saza savelisa izinto ezininzi ezikhethekileyo nezigqibeleleyo ukuze sinciphise izinga labasebenzi, siphucule ukusebenza kakuhle, kunye nokuqinisekisa ngakumbi ukuhambelana kwemveliso.

Senze njani?

Ukumamela iimfuno zabathengi

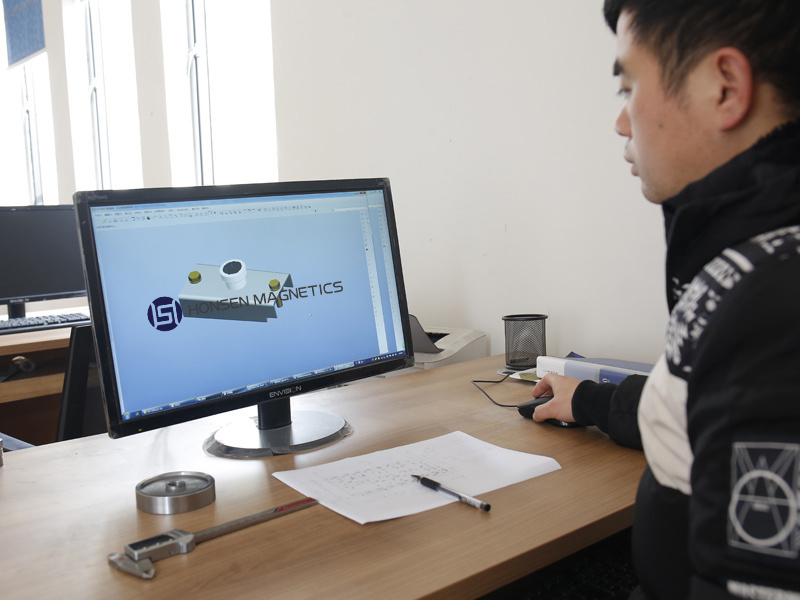

Imodeli yoYilo lweKhompyutha

Ukuze siqonde ngokupheleleyo iinjongo zomthengi, asigxininisi kuphela kwizalathisi eziphambili zokusebenza kweemveliso zamagnetic kodwa siqwalasela indawo yokusebenza yemveliso, iindlela zokusetyenziswa, kunye neemeko zokuthutha. Oku kusenza sikwazi ukuqokelela olona lwazi lubanzi luyimfuneko kwisigaba esilandelayo soyilo lwesampulu. Ngokuqwalasela zonke ezi zinto, siqinisekisa ukuba uyilo lwethu lulungiselelwe ukuhlangabezana neemfuno ezithile kunye nemingeni yomthengi ngamnye. Le ndlela yokudibanisa isenza sikwazi ukuhambisa iimveliso zemagneti ezigqwesileyo ekusebenzeni, ukuqina, kunye nokusebenza.

Sinikezela ngoncedo olubanzi ekubaleni nasekuyileni iisekethe zemagnethi ukuhlangabezana neemfuno ezithile zabathengi bethu. Ukongezelela, sithathela ingqalelo inkqubo kunye neenkqubo zokuhlanganisana ukuze siqinisekise ukusebenza koyilo. Ukuzoba kumava ethu kunye neziphumo zokubala, sinikezela ngeengcebiso ezixabisekileyo zokuphucula kuzo naziphi na iimpazamo ezikhoyo ezichongiweyo. Ngokusebenzisana nomthengi, sijolise ekufikeleleni kwisivumelwano esifanayo kuyilo lokugqibela kunye neenkcukacha. Emva kwesivumelwano, siyaqhubeka nokusayina isampula yomyalelo njengobungqina bokuzibophelela kwethu ekuziseni iimveliso zemagnethi ezikumgangatho ophezulu.

Emva kokuphucula ubuchule bethu kunye nokusebenzisa izibalo ezincediswa yi-CAE, siphumelele ngempumelelo imodeli efanelekileyo. Ugxininiso lwethu kule modeli lujikeleza izinto ezimbini eziphambili: ukunciphisa inani lemagnethi kunye nokuqinisekisa ukukhululeka kwabo komatshini. Ukwakha kwesi siseko, iinjineli zethu zivavanya ngokubanzi ubume boyilo ukwenza lula ukusetyenzwa kunye neenkqubo zokuhlanganisa. Sidibanisa iingcamango zethu kwaye sinxibelelane ngokufanelekileyo nabathengi bethu, sizama ukulungelelaniswa. Nje ukuba kufikelelwe kwisivumelwano, siyaqhubeka nokugqibezela iinkcukacha zoyilo kwaye sityikitye iiodolo zesampulu ngokuzithemba okukhulu ekusebenzeni kunye nomgangatho wemveliso yethu.

Phuhlisa iinkqubo kunye neesampuli

Ulawulo lwemveliso yebhetshi

Ukuphuhlisa iinkqubo ezineenkcukacha kunye nokwandisa iindawo zokuhlola umgangatho. Umzobo wokuqhekeka kwemveliso yesixhobo samagnetic uqalile ukuveliswa.

Iisampulu ziya kuhanjiswa kumthengi wethu ukuze amkelwe kwaye emva kokuqinisekiswa kweesampulu, siya kuqalisa inkqubo yokuvelisa isambuku.

Emva kokufumana iiodolo ezininzi, lungiselela abasebenzi ukuba basebenze, kwaye ulungiselele ngokufanelekileyo iindawo zokusebenza kunye neenkqubo. Ukuba kuyimfuneko, yila izixhobo ezikhethekileyo zokusetyenzwa ukuze kuncitshiswe amandla okusebenza kunye nokuqinisekisa ukungaguquguquki kwimveliso yebhetshi. Sinamava amaninzi kulawulo lwemveliso, kwaye kufuneka sifezekise ulawulo olunokulinganiswa kuzo zonke iinkqubo zokuqinisekisa ukuhambelana kwibhetshi nganye yeemveliso.

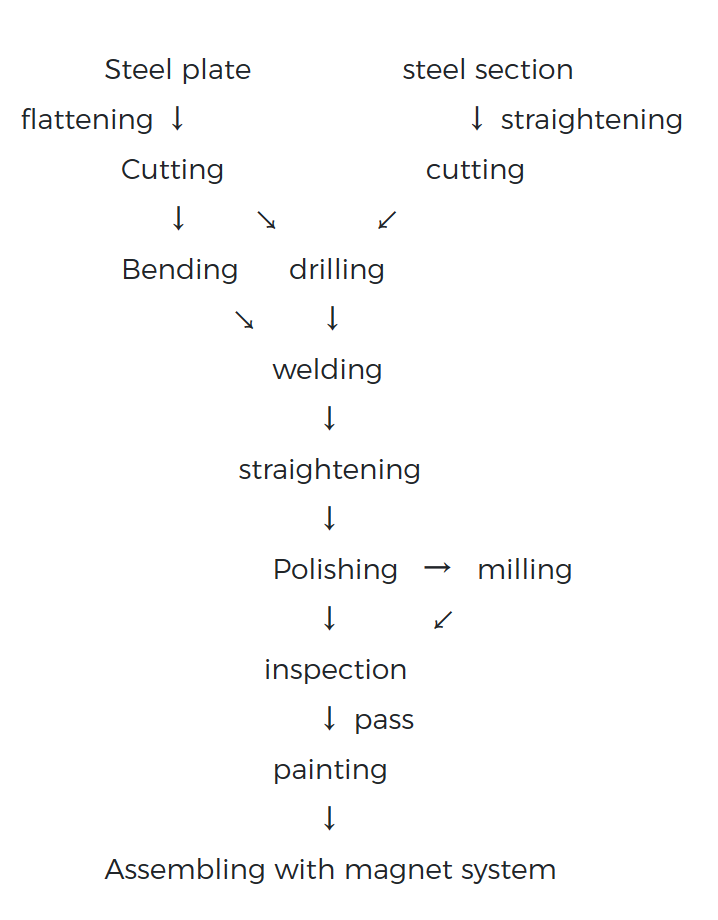

Inkqubo yeMveliso yeeNkqubo zeMagnetic Shuttering

Inkqubo yefom ye-concrete ye-U eyenziwe kusetyenziswa iipleyiti zentsimbi ngoncedo lomatshini wokugoqa okhethekileyo. Isixhobo sokusonga sinoxanduva lokudala ukhetho lwe-double-groove chamfer, i-single-groove chamfer, okanye akukho chamfer. Sikwasebenzisa izixhobo zokuthengisela ngesandla kwimagnethi ye-solder formwork ngobukhulu phakathi kwe-2-3 m. Izixhobo zethu zemveliso ziyakwazi ukuvelisa iimagnethi zetemplate ezinobude obungaphezulu kwe-100mm.

Materials template

Siqasha ngexesha lemveliso ukuze siqinisekise ubomi obude benkqubo yemagnethi oyithengayo kuthi. Sisebenzisa indibaniselwano ye-aluminium alloy kunye nensimbi engenasici ngenxa yokuqina kwazo okuphezulu kunye nokukwazi ukumelana nobushushu obugqithisileyo kunye nokunxiba. Ngaphandle koko, sisebenzisa unyango olulodwa ukukhusela iinkqubo zethu kumhlwa kunye nomhlwa. Ezi sistim zilula kakhulu ukuzigcina kuba siye sazilungisa kwangaphambili.

UMGANGATHO NOKHUSELEKO

Ulawulo lomgangatho lilitye lembombo lamaxabiso enkampani yethu. Sikholelwa ngokuqinileyo ukuba umgangatho ligazi kunye nekhampasi yeshishini. Ukuzinikela kwethu kudlulela ngaphaya kweendlela zemveli zolawulo lomgangatho - kuxhomekeke kwimisebenzi yethu. Ngokusebenzisa le ndlela, siqinisekisa ukuba iimveliso zethu zihlala zihlangabezana kwaye zigqithisa iimfuno zabathengi bethu, sibeka imilinganiselo emitsha ngokwanelisayo.

UKUPAKISHA NOKUTHUMELA

IQELA & ABATHENGI

Inkampani yethu igxile kakhulu kulawulo lomgangatho. Sikholelwa ukuba umgangatho ayisiyonto nje ingcamango, kodwa ngamandla obomi kunye nomgaqo osisikhokelo wombutho wethu. Indlela yethu idlulela ngaphaya komphezulu - sidibanisa ngaphandle komthungo inkqubo yethu yolawulo lomgangatho kwimisebenzi yethu. Ngale ndlela, siqinisekisa ukuba iimveliso zethu ziyahlangabezana kwaye zigqithise oko kulindelwe ngabathengi bethu, nto leyo ebonisa ukuzibophelela kwethu ekugqweseni.

Q&A

Q: Ngaba uyazamkela iiprojekthi ezilungiselelwe wena?

A: Siphucule kwaye siyila imilinganiselo yochungechunge, kwaye abathengi banokwenza uhlengahlengiso ngokusekelwe koku. Kwaye siyakwamkela abathengi bethu kuzo naziphi na iiprojekthi ezilungiselelweyo.

Q: Isampulu, ixabiso, kunye nexesha lokuhambisa?

A: Samkela iiodolo zesampuli. Kwiimveliso eziqhutywa rhoqo, siqhele ukuba neesampuli esitokhweni kwaye sinokukunika isampuli kusuku lwesibini. Kwimiyalelo eninzi, kuthatha iintsuku eziyi-15-20 zokuvelisa.

Q: Ubungakanani bebhetshi, ixabiso?

A: Ngokusekwe kubunzima obuthile bokuqhuba, yenza izigwebo ezijoliswe kuwe kunye neekowuteshini.

Q: Ingaba unayo nayiphi na inventory?

A: Ewe, sineemveliso ezisebenzayo rhoqo kwisitokhwe.

Q: Yintoni ebangela ukuncipha kwamandla okubamba iimagnethi zokuvala ixesha?

A: Amandla esiphumo esisisigxina kwimagnethi yokuvala anokuba buthathaka ngokuhamba kwexesha ngenxa yezinto ezimbalwa. Esinye isizathu kubukho bezinto zangaphandle, njengekhonkrithi, iifayili zentsimbi, okanye ifilimu, kumphezulu ongezantsi wemagnethi. Xa ezi zixhobo ziqokelelana, zithintela amandla emagnethi ukuba ancamathele ngokukhuselekileyo eqongeni, okukhokelela ekunciphiseni amandla okubamba. Ukongeza, ukungahambi kakuhle kwemagneti kunokubangela ukuba buthathaka. Xa ingalungelelaniswanga kakuhle, umazibuthe akakwazi ukuseka uqhagamshelo olomeleleyo, nto leyo ekhokelela ekunciphiseni ukusebenza kwayo iyonke. Kubalulekile ukujongana nale miba ngokukhawuleza ukugcina amandla afunekayo okubamba kunye nokuthintela ukwehla ngakumbi kwemagnethi ekuhambeni kwexesha.

Q: Ndingawunqanda njani umonakalo kwimagnethi yam?

A: Ukugcina ingqibelelo yemagnethi yakho kunye nokuthintela umonakalo, qwalasela la manyathelo alandelayo:

-Bamba ngenkathalo: Yiphathe ngobunono imagnethi yakho kwaye uphephe ukuyiwisa, ukuyibetha, okanye ukuyithobela kumandla agqithisileyo okanye impembelelo. Khumbula ukuba iimagnethi zinezinto ezibuthathaka ezinokonakala xa zingaphathwanga kakuhle

-Kulumkele ukusebenzisana kwemagnethi ukuya kumazibuthe: Sukuvumela iimagnethi ukuba zidibane, njengoko zinokutshiphuza ngokulula, ziqhekeke okanye ziqhekeke. Zigcine zahluliwe okanye usebenzise imathiriyeli engeyiyo eyemagnetic njengezithintelo xa uzigcina okanye uzithutha.

-Khusela kumaqondo obushushu agqithisileyo: Amaqondo obushushu aphezulu anokuchaphazela ukusebenza kunye nemagnethi yemagnethi, ngelixa amaqondo obushushu aphantsi kakhulu anokubenza babe brittle kwaye babe sengozini yokwaphuka. Gcina iimagnethi kude nemithombo yobushushu obugqithisileyo kwaye uphephe ukubabeka esichengeni sobushushu obuqhaqhazelisa amazinyo.

-Coca ngononophelo: Xa ucoca umazibuthe wakho, sebenzisa ilaphu elithambileyo okanye ibrashi ukususa nabuphi na ubumdaka okanye inkunkuma ngobunono. Kuphephe ukusebenzisa izinto ezirhabaxa okanye iikhemikhali ezirhabaxa, njengoko zinokukrwela okanye zonakalisa umphezulu wemagnethi.

-Gcina ngokufanelekileyo: Khusela umazibuthe wakho kwimagnethi ngokuyigcina kwisingxobo esingesomagnetic okanye kwipakethe. Oku kuthintela umtsalane ongeyonjongo kwezinye izinto kwaye kunciphisa umngcipheko womonakalo.

Q: Ngaba kuqhelekile ukuba iimagnethi zibe namava okuhla kwamandla ngokuhamba kwexesha?

A: Kuqhelekile ukuba umazibuthe abe namava okuhla kwamandla ngokuhamba kwexesha. Ngelixa zonke iimagnethi ziya kuphulukana noxinzelelo ngexesha,Honsen Magneticsisebenzisa iimagnethi ezikumgangatho ophezulu, ezinexabiso eliphantsi lelahleko le-1% kuphela kwiminyaka eli-10 yokuqala yokusetyenziswa. Oku kuthetha ukuba oomazibuthe bethu bagcina amandla kunye nokusebenza kwabo ixesha elide xa kuthelekiswa nezinye iimagnethi.