IBar yesihluzi seMagnetic

Ibar yesihluzi samagnetic sisixhobo esiqhele ukusetyenziswa ukucoca ukungcola kulwelo kunye neegesi.Esi sixhobo sinentonga enye okanye ngaphezulu ezithi zibambe kwaye zihluze ubumdaka kulwelo okanye kwimigca yerhasi ukukhusela izixhobo emonakalweni.

I-Magnetic filter rods zinokuhluza ulwelo, iigesi, umgubo kunye nemathiriyeli eyomeleleyo kakuhle.Ingaba iphatha amanzi, i-oyile, i-fuel okanye isitashi, iglasi, iiminerali, njl., inokufumana iziphumo ezilungileyo.

Iintsimbi zesihluzi zemagneti zisebenza kakuhle ukuhluza.Ngenxa yepropathi ye-adsorption yayo, inokuhluza ukungcola okuncinci ngokufanelekileyo, ngaloo ndlela iphucula umgangatho kunye nokucoceka kweemveliso.

Iintsimbi zesihluzi zeMagnetic kulula ukuzicoca, ukuzigcina nokubuyisela ezinye.Ngenxa yesakhiwo sayo esilula, sinokuchithwa ngokulula kwaye sicocwe ukugcina ukusetyenziswa kakuhle.Ukuba ifuna ukutshintshwa, vele ubuyisele ibha yokucoca umazibuthe.

Izihluzi zeMagnetic zinoqoqosho kwaye ziyasebenza.Xa kuthelekiswa nezihluzi eziqhelekileyo, izihluzi zemagnethi azidingi amandla ongezelelweyo okanye iindleko kwaye zinokwenza imisebenzi yokucoca ngokukhawuleza nangempumelelo, ngoko ukunciphisa iindleko zokuvelisa kunye nokwandisa imveliso.

IiNgcaciso zeBar yesihluzi seMagnetic

Ubungakanani: Ubungakanani bezintonga zokucoca magnetic kufuneka zikhethwe ngokobungakanani bombhobho kunye neemfuno zokuhamba.Ubungakanani ngokuqhelekileyo buchazwa ngeeparamitha ezifana nobude kunye nobubanzi.

| Inqaku lenqaku. | Ububanzi (mm) | Ubude (mm) | Umphezulu weFlux (Gauss) | Inqaku lenqaku. | Ububanzi (mm) | Ubude (mm) | Umphezulu weFlux (Gauss) |

| 25×100 | 25 | 100 | 1500-14000GS | 25×600 | 25 | 600 | 1500-14000GS |

| 25×150 | 25 | 150 | 1500-14000GS | 25×650 | 25 | 650 | 1500-14000GS |

| 25×200 | 25 | 200 | 1500-14000GS | 25×700 | 25 | 700 | 1500-14000GS |

| 25×250 | 25 | 250 | 1500-14000GS | 25×750 | 25 | 750 | 1500-14000GS |

| 25×300 | 25 | 300 | 1500-14000GS | 25×800 | 25 | 800 | 1500-14000GS |

| 25×350 | 25 | 350 | 1500-14000GS | 25×850 | 25 | 850 | 1500-14000GS |

| 25×400 | 25 | 400 | 1500-14000GS | 25×900 | 25 | 900 | 1500-14000GS |

| 25×450 | 25 | 450 | 1500-14000GS | 25×950 | 25 | 950 | 1500-14000GS |

| 25×500 | 25 | 500 | 1500-14000GS | 25×1000 | 25 | 1000 | 1500-14000GS |

| 25×550 | 25 | 550 | 1500-14000GS | 25×1500 | 25 | 1500 | 1500-14000GS |

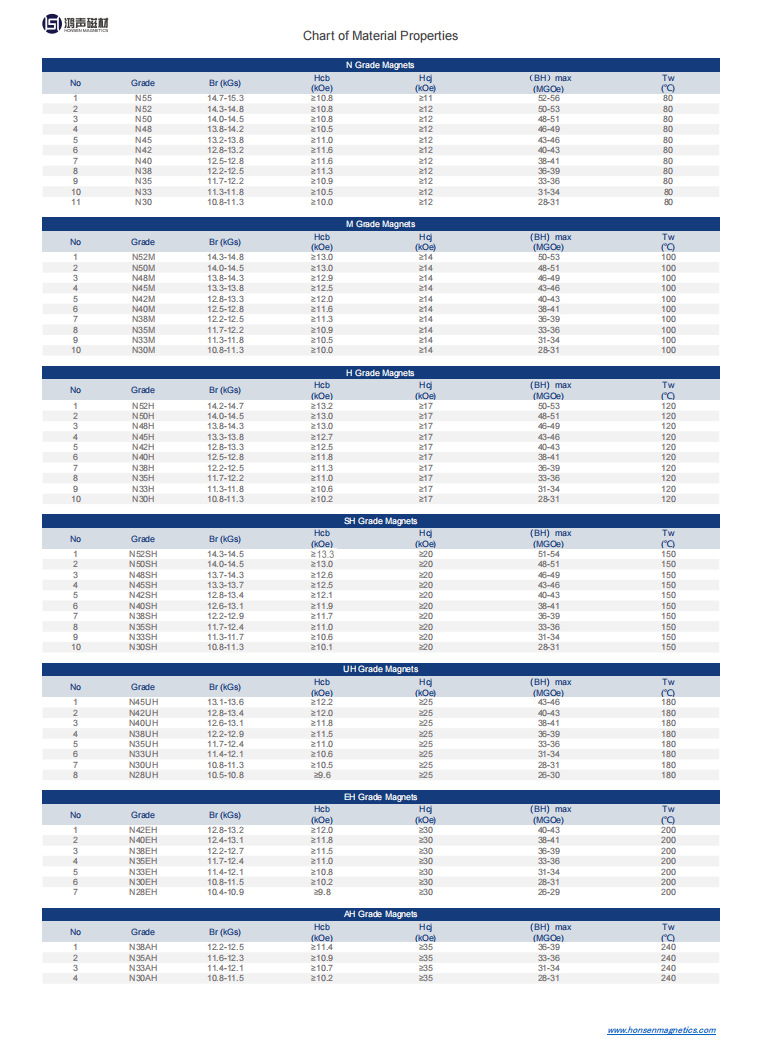

Iqondo lobushushu: Izinto kunye nezindlu zebar yesihluzi samagnetic kufuneka zikwazi ukumelana nobushushu obuphezulu okanye obuphantsi bemeko yesicelo sayo.

| IBanga | Max.ukusebenza Temp | Curie Temp | Ibakala magnetic exhaswayo |

| N | 80℃/176℉ | 310℃/590℉ | N30-N55 |

| M | 100℃/212℉ | 340℃/644℉ | I-N30M-N52M |

| H | 120℃/248℉ | 340℃/644℉ | N30H-N52H |

| SH | 150℃/302℉ | 340℃/644℉ | I-N30SH-N52SH |

| UH | 180℃/356℉ | 350℃/662℉ | N28UH-N45UH |

| Eh | 200℃/392℉ | 350℃/662℉ | N28EH-N42EH |

| AH | 240℃/464℉ | 350℃/662℉ | N30AH-N38AH |

I-Curie Temp: ekwabizwa ngokuba yiCurie point okanye imagnethi yotshintsho, yithiyori yomda wobushushu osebenzayo wezinto ezinobuchwephesha, ngaphaya kobushushu beCurie, iipropathi zemagneti zemagnethi ziya kunyamalala ngokupheleleyo.

I-Max.Working Temp: Ukuba ubushushu obuphezulu bokusebenza bugqithisiwe, imagnethi yemathiriyeli kazibuthe iya kwenziwa demagnetic kwaye ilahleko engenakubuyiseka iya kwenzeka.

Ubudlelwane: kokukhona ubushushu beCurie buphezulu, kokukhona ubushushu bokusebenza bezinto eziphathekayo, kunye nozinzo olungcono lobushushu.

Amandla emagnethi: Amandla omagnetic webar yesihluzo sozibuthe axhomekeke kuhlobo kunye nenani lemagnethi ngaphakathi kuyo.Amandla ombane anamandla aphucula ukusebenza kakuhle kokuhluza kodwa unokuchaphazela isantya sokuhamba kolwelo okanye irhasi.

IMaterial: Imaterial yentonga yokucoca imagnethi kufuneka ihambelane nolwelo okanye irhasi ehluzwayo kwaye akufunekanga ibe phantsi komhlwa.

Ngenxa yokumelana nokugqwesa kwayo okugqwesileyo, intsimbi engatyiwa sisixhobo esisetyenziswa ngokuqhelekileyo kwizicelo ezininzi.Nangona kunjalo, kwizicelo ezifuna umgangatho ophezulu wokumelana nokugqwala, kubalulekile ngokulinganayo ukukhetha ibakala eliphezulu lezinto zensimbi ezingenasici.Imizekelo ibandakanya i-316 okanye i-316L, efanelekileyo kakhulu kumashishini afana nokutya okanye ukulungiswa kweekhemikhali, apho ukuvezwa kweekhemikhali ezinobungozi okanye ukufuma okuphezulu kunokwenzeka.

Ukuba awuqinisekanga ukuba yeyiphi imathiriyeli efanelekileyo kwiimfuno zakho zesicelo, nceda uzive ukhululekile ukuqhagamshelana nathi.Iqela lethu leengcaphephe lingakunika iingcebiso kunye nesikhokelo ukukunceda wenze isigqibo esinolwazi.E-Honsen, sizibophelele ekuqinisekiseni ukuba ufumana ezona mathiriyeli zibalaseleyo kwisicelo sakho, kwaye sihlala silapha ukunceda.

Ukuhlohla:

Isiphelo semagnethi sinemisonto eyindoda

Isiphelo umazibuthe sinemisonto yabasetyhini

Iziphelo umazibuthe ziwele welding

Zombini iziphelo zikamazibuthe zinokunyuswa ngokwesiko ukuhlangabezana neemfuno zakho ezithile, kunye nokhetho olufana nendoda, ibhinqa, kunye ne-flat weld.Nokuba yeyiphi na iimfuno zakho, sinokubonelela ngemagnethi echanekileyo ukuqinisekisa inkqubo yokufaka engenamthungo.

Ungayikhetha njani ngokufanelekileyo ibha yokucoca yamagnetic?

Isantya sokuhamba: Misela isantya sokuhamba kunye nobushushu bokusebenza obufuna ukuhluzwa.Oku kunceda ukumisela ukuba zingaphi na iintonga zokucoca ezinozibuthe ezifunekayo kwaye loluphi uhlobo lwesihluzo semagnethi.

Amandla emagnethi: Khetha amandla afanelekileyo emagnethi ngokusekwe kudidi kunye nobukhulu bobumdaka obuza kususwa.Ngokwesiqhelo, izihluzi zemagnethi ezomeleleyo ziyafuneka kwizinto ezinkulu.

Ubume: Khetha imilo yebha yesihluzo esifanelekileyo ngokweyona ndawo yofakelo kunye neemfuno zesihluzi.

Isixhobo: Khetha imathiriyeli efanelekileyo ukuze ilungele imidiya eyahlukeneyo yolwelo kunye nokusingqongileyo, njengentsimbi engatyiwa, i-titanium alloy, imathiriyeli esisigxina yamagnetic, njl.

Iindleko zobomi kunye nokugcinwa kwazo: Khetha izihluzi zemagnethi eziphila ubomi obude kunye neendleko eziphantsi zogcino ukunciphisa iindleko zokusebenzisa kunye neendleko zokuzigcina.

Ukusetyenziswa kwebha yesihluzo samagnetic

Umzi-mveliso wePlastiki: Iintsimbi zokucoca imagnethi zihlala zisetyenziswa kwinkqubo yokujikeleza okupholisa koomatshini bokubumba inaliti, ii-extruders, oomatshini bokubumba obuvuthelayo kunye nezinye izixhobo zokususa iitshiphusi zentsimbi, umgubo wentsimbi kunye nobunye ukungcola ukukhusela ukusebenza okuqhelekileyo kwesixhobo.

Umzi-mveliso wamachiza: izihluzi zemagnethi zinokususa ukungcola okunje ngeetshiphu zentsimbi kunye nezikhonkwane zentsimbi kumayeza angamalwelo ukuqinisekisa ukucoceka kunye nomgangatho wamachiza.

Ishishini lokutya: I-Magnetic filter rods isetyenziswa ngokubanzi kwimigca yemveliso yokutya ukususa ukungcola kwesinyithi ekutyeni ukuqinisekisa umgangatho kunye nokhuseleko lweemveliso.

Umzi-mveliso womatshini: Iintsimbi zokucoca imagnethi zidla ngokusetyenziswa kumatshini wokupholisa isixhobo sokususa iitshiphusi zentsimbi, isanti kunye nobunye ukungcola ukwandisa ubomi besixhobo kunye nokuphucula ukuchaneka komatshini.

Umzi-mveliso werhasi: Iintsimbi zokucoca imagnethi zinokususa iitshiphu zentsimbi kunye nobunye ukungcola kwirhasi yendalo kunye nerhasi elulwelo ukukhusela ukusebenza ngokukhuselekileyo kwezixhobo zerhasi.

Umzi-mveliso weMichiza: Isetyenziselwa ukususa amasuntswana e-ferromagnetic kunye neeoksidi ezinqunyanyiswe kwisisombululo.

Ishishini lephepha: lisetyenziselwa ukususa ubumdaka be-ferromagnetic kwinkqubo yokwenza iphepha ukuqinisekisa umgangatho wephepha.

Ushishino lwasezimayini: lusetyenziselwa ukwahlula izimbiwa eziqulathe intsimbi kwintsimbi ekrwada kunye nokuphucula ukusebenza kakuhle kokulungiswa kwezimbiwa.

Ishishini lokucocwa kwamanzi: izihluzi zemagnethi kunye nemivalo zizixhobo ezisebenzayo zokususa isinyithi, i-manganese kunye nezinye isinyithi emanzini, zenza ukuba kukhuselekile ukusela kunye nezinye izinto.

Umzi-mveliso welaphu: Izihluzi zemagneti kunye nemivalo zisetyenziswa kwimveliso yelaphu ukususa ungcoliseko lwentsimbi emalaphini, ukuqinisekisa umgangatho wemveliso kunye nokuthintela umonakalo koomatshini.

Umzi-mveliso weemoto: Izihluzi zemagneti zisetyenziswa kwimveliso yeemoto ukususa izinto ezingcolisa isinyithi kwisipholisi kunye nezithambisi ukuthintela umonakalo kwizixhobo kunye nokuqinisekisa umgangatho wemveliso.

Izinto Eziluncedo Zethu

Fumana ibha yokucoca imagnethi ejikelezileyo kwiimfuno zakho!Iinduku zethu zemagnethi ziyafumaneka xa ucelile.

1.Iintsimbi zethu zokuhluza kazibuthe kunye nemivalo zenziwe ngetyhubhu yentsimbi ekumgangatho ophezulu kwaye iza nemagnethi ye-neodymium yokusebenza ephezulu ukuze ilungele isicelo sakho.Usebenzisa izihluzi zemagnethi zomntu ngamnye, unokwakha okanye ulungise izixhobo zakho zokwahlula imagnethi.

2.Khetha amandla kazibuthe afanele iimfuno zakho!Iimveliso zethu zifumaneka ngamandla kazibuthe ukusuka 1500-14000 gauss ukuhlangabezana neemfuno zakho ezithile.Iibha ezineemagnethi ezomeleleyo ze-neodymium zinokuba nexabiso lemagnethi ukuya kuthi ga kwi-14,000 ye-gauss kumphezulu wazo.

I-3.Ifanelekile ngokufanelekileyo kwiintonga zethu ezitywinwe ngokupheleleyo kunye ne-welded!Sinikezela ngeephelo ezidityanisiweyo ezenziwe ngokwezifiso zendoda, yabasetyhini okanye ethe tyaba ukuhlangabezana neemfuno zakho ezithile.

4.Yonke imivalo yethu yamagnetic ayinamanzi, iqinisekisa ukuba isebenza ngokufanelekileyo nakwiindawo ezimanzi okanye ezifumileyo.

5.Imivalo yethu yokucoca yamagnetic kunye neentonga ziphuculwe kakuhle ukubonelela ngembonakalo yobungcali kunye nokuqinisekisa ukuba kulula ukuzicoca nokugcina.

Ngemathiriyeli yethu esemgangathweni kunye neenketho eziguquguqukayo, unokwakha ngokuzithemba okanye uguqule izixhobo zakho zokwahlula kazibuthe.

Ixesha lokuposa: Apr-13-2023